Ladies and gentlemen, I'd like to introduce to you the Claro Cart! This nifty rolling bar cart, made of stainless steel and shimmery Claro walnut, is a collaboration with my good friend and talented woodworker Caty Moniz!

I first became friends with Caty because we worked together at Box headquarters in Los Altos. On our commute home one day about a year ago, we realized that we both loved making furniture. We had a good laugh when we discovered that she had finished wood slabs lying around her garage that didn't have table bases; meanwhile, I had a steel table base in my studio without a top. We joked about collaborating on a piece of furniture one day -- I'd do the metal, and she'd do the wood.

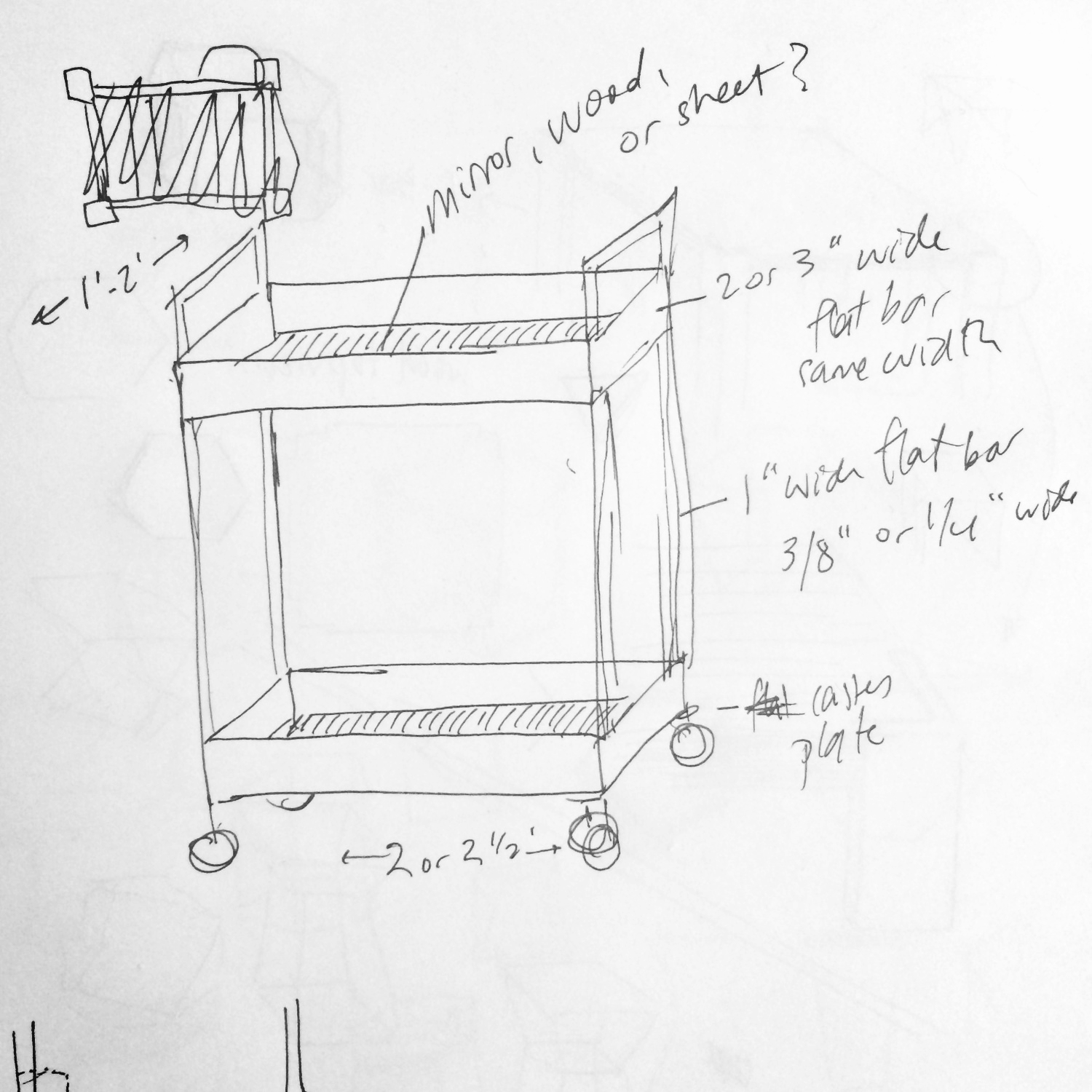

And then a few months ago, we decided to go for it! We came up with a simple, elegant design for a rolling bar cart that would show off the contrast of dark wood against bright stainless steel.

Caty hunted down a gorgeously marbled piece of solid Claro walnut while visiting family just outside of Jefferson, Oregon. Claro walnut is known for its striking figuring, often showing subtle intermixed colors of reds, browns, yellows, purples, and blacks in its grain. The piece chosen for the bar cart was no exception, with a lovely blond streak running through one of the pieces. Caty cut and sanded the walnut, increasing the grit until achieving a silky finish. In order to bring out the natural colors in the figuring of the wood, she finished the pieces with a few coats of ProFin, an oil-based finish -- no staining for this beauty!

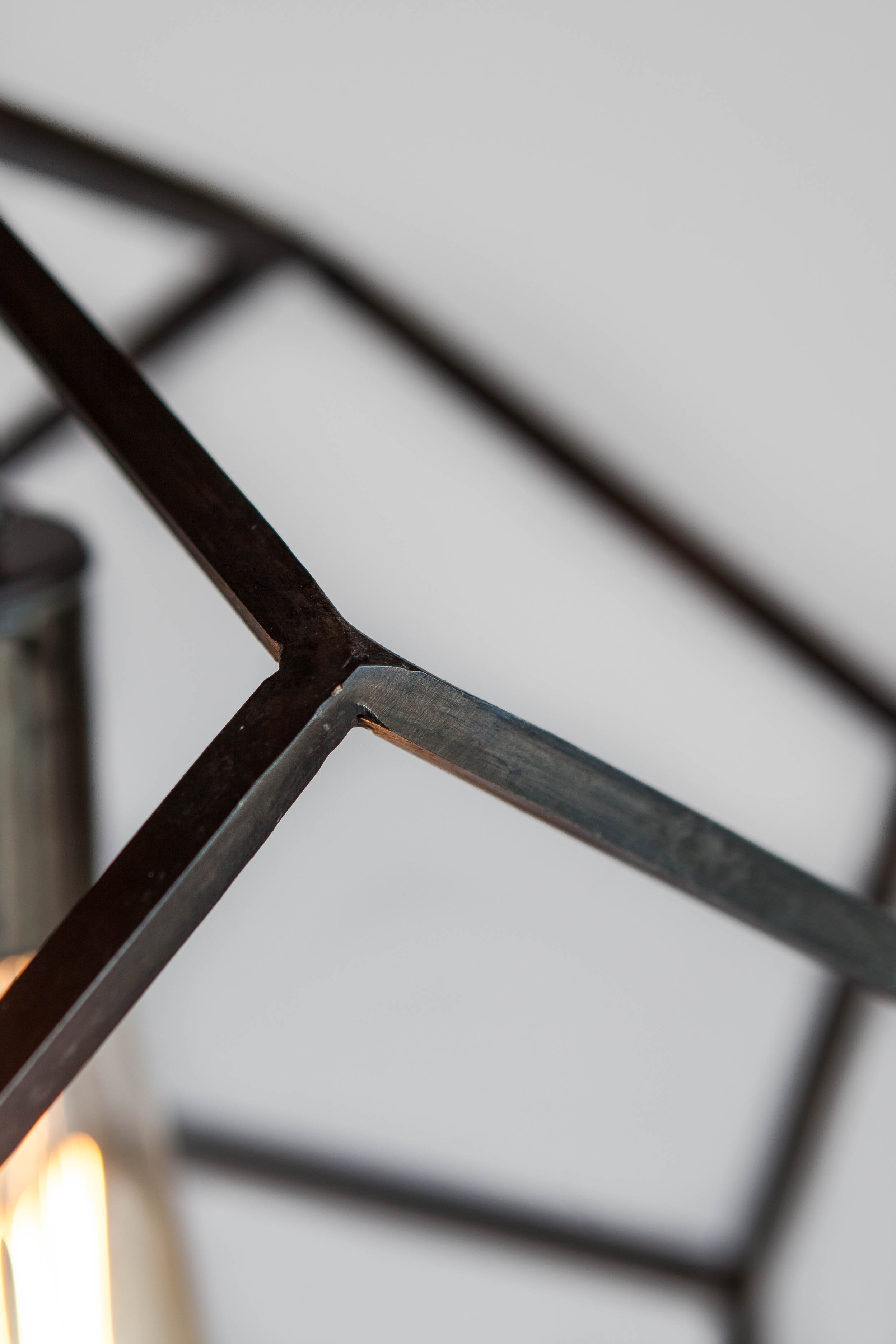

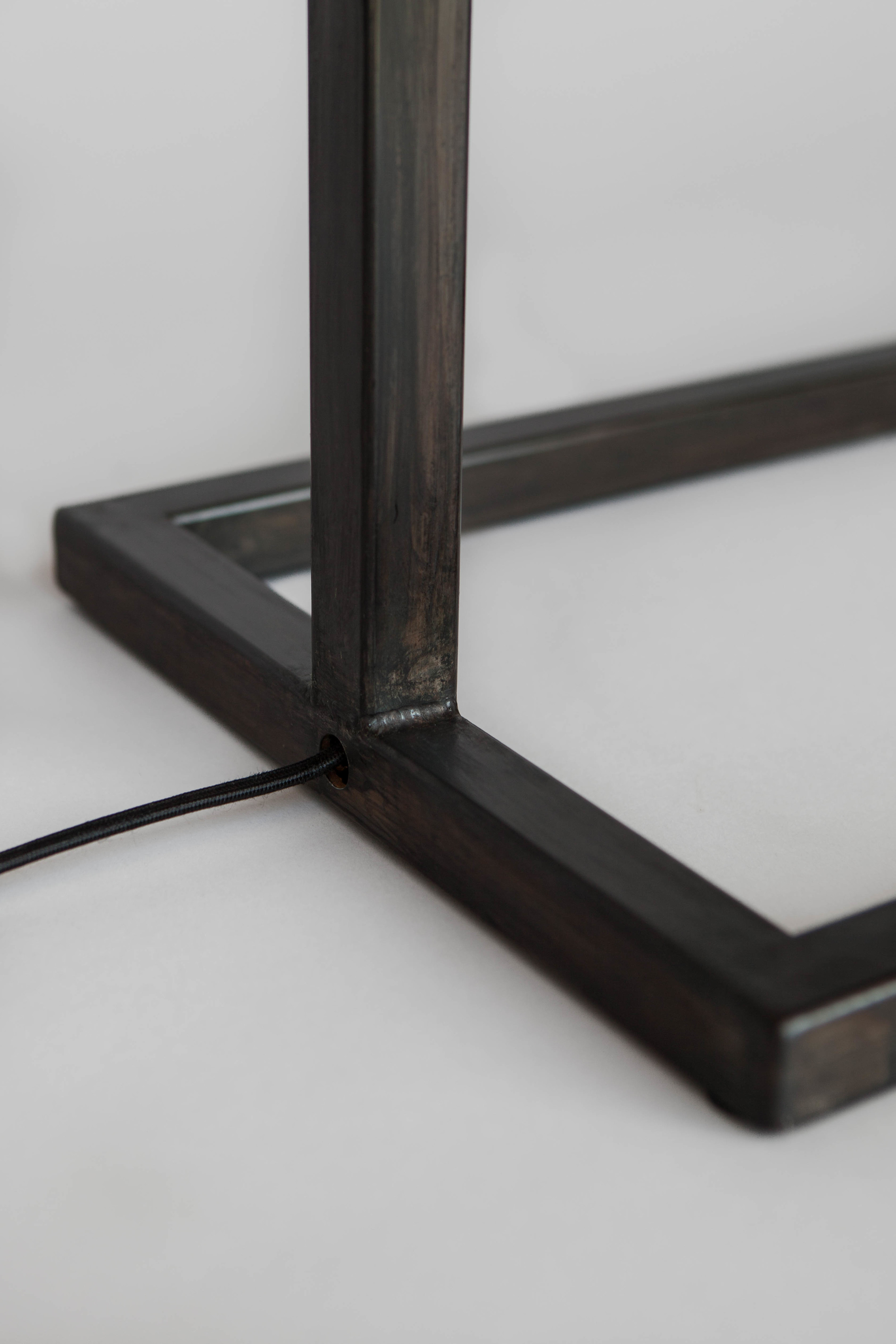

Meanwhile, I picked up a some stainless steel flatbar from my favorite woman-owned steel supplier. I cut the bar down to smaller lengths, ground down the ends a bit to create channels for welding, and then TIG welded the frame together. I sanded the entire surface with an angle grinder to create a lightly-textured satin finish. Finally, I welded the locking stainless steel casters to the frame, careful to not melt the rubber wheels.

After working on our respective pieces, Caty and I met up for dinner to join the metal and the wood. It was magical seeing it finally come together!

Here are some behind-the-scenes photos Caty and I took throughout the process of designing and building the cart:

Caty and I had so much fun making the Claro Cart together, and we hope you like it. It's available for purchase in the Elektra Steel shop for $1800. It will also be on display at The Crucible's Spring Open House this Saturday, April 11, 2015, from 12-5pm. Cheers!